Robotics is transforming warehouse automation through the deployment of Autonomous Mobile Robots (AMRs) and advanced robotic arms. These technologies enhance operational efficiency by optimizing inventory management and facilitating precise navigation. The integration of robotics reduces human error and increases productivity in sorting and packaging processes. However, the impact of these innovations extends beyond mere efficiency. Understanding the implications for safety and labor costs reveals a deeper layer of transformation in warehouse operations.

The Rise of Autonomous Mobile Robots in Warehousing

The emergence of autonomy in warehousing has fundamentally transformed operational efficiencies, primarily through the integration of Autonomous Mobile Robots (AMRs).

These systems leverage advanced robot navigation techniques and algorithms for precise route planning, enhancing task optimization.

Enhancements in Inventory Management Through Robotics

As inventory management becomes increasingly complex in modern warehouses, robotics offers innovative solutions that streamline and enhance the accuracy of stock handling processes.

Robotic integration facilitates real-time inventory tracking, minimizing discrepancies and improving operational efficiency. By automating data collection and analysis, robotics not only reduces human error but also allows for more agile inventory management, ultimately empowering businesses to respond swiftly to market demands.

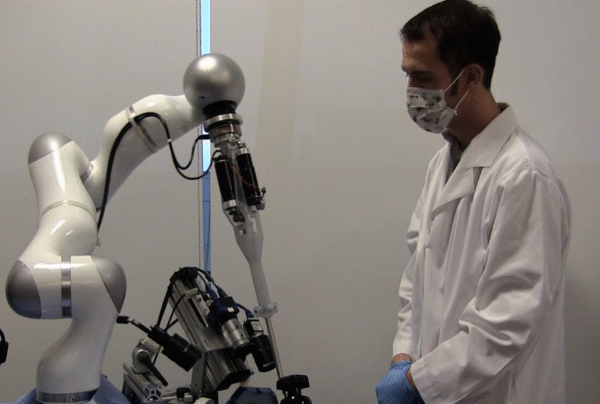

See also: How Robots Are Assisting in Surgery

Robotic Arms: Revolutionizing Sorting and Packaging

Robotic arms have emerged as a key component in the evolution of sorting and packaging processes within warehouses, complementing advancements in inventory management.

These systems facilitate robotic sorting, enhancing efficiency and accuracy in item classification.

Furthermore, automated packaging solutions streamline the finalization of orders, reducing human error and expediting throughput.

The integration of robotic arms significantly optimizes operational capabilities in modern warehouse environments.

Improving Safety and Reducing Labor Costs With Robotics

While traditional warehouse operations often expose workers to hazardous conditions, the introduction of robotics has significantly enhanced safety protocols and reduced labor costs.

Automated systems minimize human exposure to dangerous tasks, thereby mitigating injury risks and ensuring compliance with safety regulations.

Additionally, robotics streamline operations, leading to notable cost efficiency by decreasing reliance on manual labor and optimizing resource allocation within the warehouse environment.

Conclusion

In the evolving landscape of warehouse automation, robotics serves as the cornerstone of efficiency and safety. As Autonomous Mobile Robots glide seamlessly through aisles, and robotic arms deftly manipulate packages, they transform traditional operations into a symphony of precision and productivity. This integration not only curtails labor costs but also cultivates a safer work environment, painting a future where human ingenuity and robotic efficiency coexist harmoniously, driving the industry toward unprecedented operational excellence.